What are the fundamentals of the material requirements plan?

In the series of videos on inventory management, multiple methods of planning like economic order quantity, the P-type system, the Q-type system, etc have been explained. All of those are primarily used for independent demand items like cars, bicycles, etc. However, those systems are not effective when it comes to dependent demand items like tires and frames. Cars and bicycles are known as items with independent demand because the demand comes directly from the market. Whereas once the demand for these independent items is received, in order to assemble these items, you require a lot of items such as tires, frames, etc. Since the requirement for tires is dependent on the requirement for cars, this is known as a dependent demand. Now again, these items like tires and frames can also be independent demands because you can directly receive a demand from the market in the form of spares. However, primarily, these are dependent-demand items. Now, while planning or producing finished goods using assembly operations, there are many items that are themselves sub-assemblies.

The MRP, or material requirements planning system, is used for planning the future requirements of the dependent demand items. Now, MRP basically requires some inputs and then generates the outputs.

What the inputs are that go into the MRP system and what the outputs are that it generates.

- So, the first input required is the inventory status (that is, the number of items in the inventory). Now, before you start figuring out how much of each component is required to be procured from the supply, you first need to understand how many of these items you already have in your inventory. So, this inventory status becomes one of the key inputs into the MRP system.

- The second input is the master production schedule, also known as the MPS, and basically, this is nothing but the number of finished goods to be produced in the near future using these dependent demand items. So how many X need to be produced on which date is basically your master’s precious schedule, i.e., how much production needs to be done on which date.

- And the third input into the MRP system is the number of units of the item required for manufacturing a single unit of the finished product, known as the bill of materials. Now, once these inputs are fed into the MRP system, the outputs are generated, so I just want to give a very brief understanding of what these inputs are. So basically, you are telling the master production schedule what and how many of the final goods are to be manufactured. So, this X is only 1, but there could be multiple finished goods that need to be manufactured. What does it consist of? In order to manufacture these, how much of each component is required? And what of all this is already available in your inventory?

So, this kind of gives you the entire current supply situation that you already have in your inventory, what needs to be generated or produced in the future, and what it will take to produce this in the future.

After these inputs have been received, the MRP engine generates the output, so let’s look at the outputs.

- Planned orders report

- Order release report

- Order change report

What is a bill of materials?

The bill of materials is one of the key inputs to MRP planning. MRP is the material requirement planning process, and the bill of materials is one of the key inputs to that process. So let us understand what a bill of materials is. In MRP (materials requirements planning), the bill of materials is a record of all the components; it tells what the components of an item are. The parent-component relationships There might be components and their parents within the end item. So, this BOM talks about the multiple parent component relationships and the usage quantities, which means how many components for each parent are required.

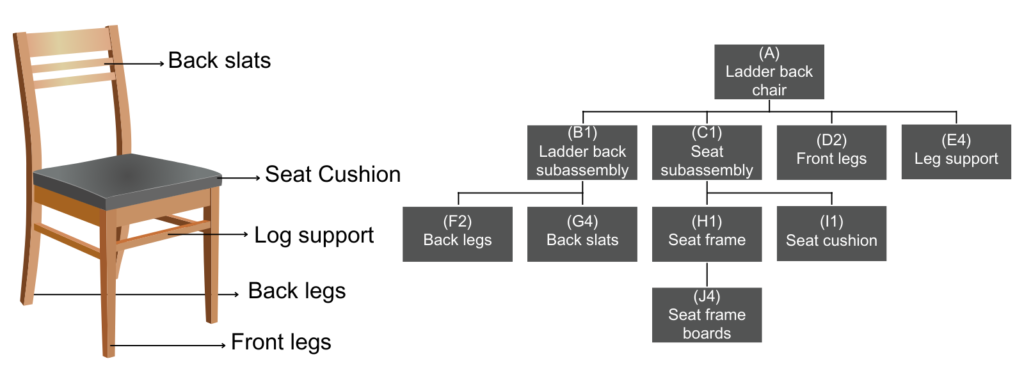

As you can see in this image, this is the bill of materials for this chair. The BOM shows that the chair is made from a ladder-back subassembly. So, the end product is the ladder-back chair, which is made up of the ladder-back subassembly, a seat subassembly, front legs, and leg supports. The ladder-back subassembly is made from back legs and back slats. The seat subassembly, which is this part here, is made up of the seat frame and seat cushion. So, this is the frame. That is, you have four sides here. This is the frame and the seat cushion. And the seat frame is made up of four seat frame boards. As you can see here, these are the four seat frame boards and one seat cushion.

Now, as you can see, we have denoted each of these with a letter, so the North product is A. Then you have B, C, D, E, F, G, H, I, and J. Now items A, B, C, and H are parents. These are parents because they all have at least one component. A has so many components. If you look at B, then it has this back slat, and this has a component. Seat assembly has these as components, and seat frame assembly also has seat frame boards as components. Now, we briefly discussed that the breakup of the parent into the components also specifies the usage quantity, so for one ladder back subassembly, you need two back legs and four back slats. Similarly, for each seat frame, you need four seat frame boards. And as you can see in this figure, 2, 4, 1, etc. are mentioned in parenthesis here in this BOM.

So, as we can see, we have the components, we have the parent component relationships, and we have the usage quantities. There are now four terms that are frequently used to describe the inventory items. So let’s look at those.

- The first is the end item. Now, this is the final product that is sold to the customer, so in this case, A is the end product. It is a parent but not a component item. A is an end item. In terms of accounting, this inventory of end items is classified either as WIP, that is, work in progress if the work remains to be done, or as finished goods.

- The second type of item is known as an intermediate item. The next three intermediate items in this BOM are B, C, and H. So, B, C, and H are items that have at least one parent and at least one component in terms of accounting. The inventory of intermediate items is classified as work in progress, whether it is completed or still on the shop floor. So, it is classified as a work in progress.

- The third type of item is called a sub-assembly. Now, a sub-assembly is an intermediate item that is assembled as opposed to being transformed by other means, and items B and C are sub-assemblies. So, B, C, and H were intermediate items, but only B and C are sub-assemblies.

- The fourth type is known as purchase items. It comes from a supplier, but it has one or more parents (D, E, F, G, I, and J in this example). In terms of the accounting statement, inventory of purchase items is treated as raw materials.