What is operations scheduling?

Let’s first comprehend the fundamental ideas behind it. One of the responsibilities of the operations manager is scheduling. It is a crucial component of job shop processing. Scheduling in operations management focuses on how to optimize available capacity while taking into account technological production limits. At one or more workstations, it is frequently necessary to process many jobs. Usually, these stations can be used to carry out a range of duties. Waiting lines may begin to form if schedules are carefully arranged to minimize bottlenecks. Scheduling in operations management typically occurs after a number of managerial choices have been taken. Planning for emergencies like fire protection, for instance, necessitates a review of the location, equipment, and employees. Work schedules cannot be established until this has been planned. A company can achieve its strategic objectives with effective scheduling.

Example of operations scheduling:

Assume you have the M1, M2, M3, and M4 machines. Let the various positions be A, B, C, D, E, and F. Which job should be processed first? This will be based on the priority of the job. So, between A and B, sequencing or prioritization will decide which job needs to be done first.

Consider machines M1 to M4 are in the milling department. Once milling is done, they may have to go to other departments such as drilling, grinding, packing. This is called planning the route of movement of material from one department to another during processing i.e., which departments will these jobs flow through.

After planning these activities, a dispatch list is issued to various work centers. It contains information about the work center at which a customer order should be processed, the sequence of orders to process, and the amount of time the processing should take. What if operations planning and scheduling is not done in an organization?

Let us understand this through an example.

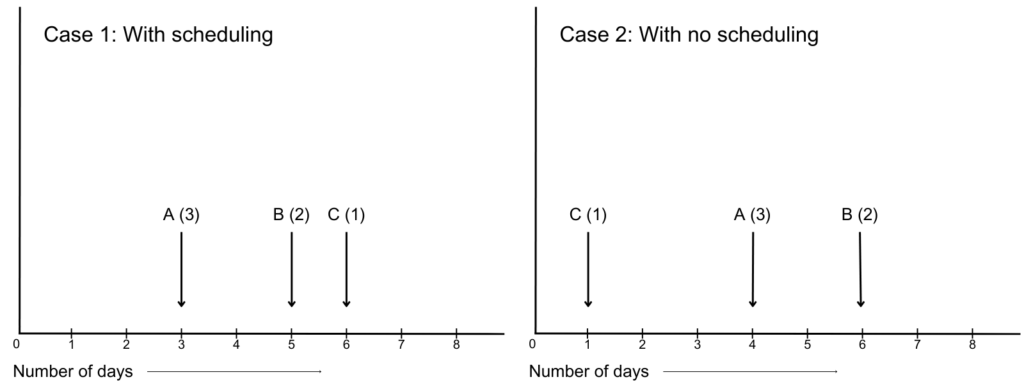

Let A, B and C be three different activities which take 3, 2 and 1 day to complete.

In case 1, the activities have been scheduled as per the priorities, with fixed dates as per their time frame of completion. But what if scheduling is not done and all the activities are jumbled up like case 2?

Absence of proper scheduling may lead to many problems like delays in meeting due dates of customer orders, high inventory, higher set up time of machines, higher overall completion time and uneven workload.

Hence, to avoid such problems, operations scheduling is a must.

What is forward and backward scheduling?

Forward scheduling works on the principle of starting as early as possible. For example, there is an order due on day 6, and the manufacturing takes 3 days. Suppose we are on day 0 today. If we apply forward scheduling, we are finishing the job as early as possible. What happens is, even if we finish manufacturing early, some customers want the product on that particular day itself (day 6 in this example). So, for 3 days, it’ll be in the inventory. Hence, inventory goes up in forward scheduling.

Backward scheduling works on the principle of scheduling as late as possible. For example, there is an order due on day 6, and the manufacturing takes 3 days. We will start on day 3 even if the machine has been available since day 0. Here, the inventory is lower, but the risk of getting delayed is higher. Because if there are some urgent orders on day 3, one of the orders will have to be compromised.

What is finite and infinite loading?

Let us understand another important term of scheduling types in operations management, which is finite and infinite loading. Before jumping on to this topic, first understand what is loading? Loading means assigning tasks to machines or other resources like workers.

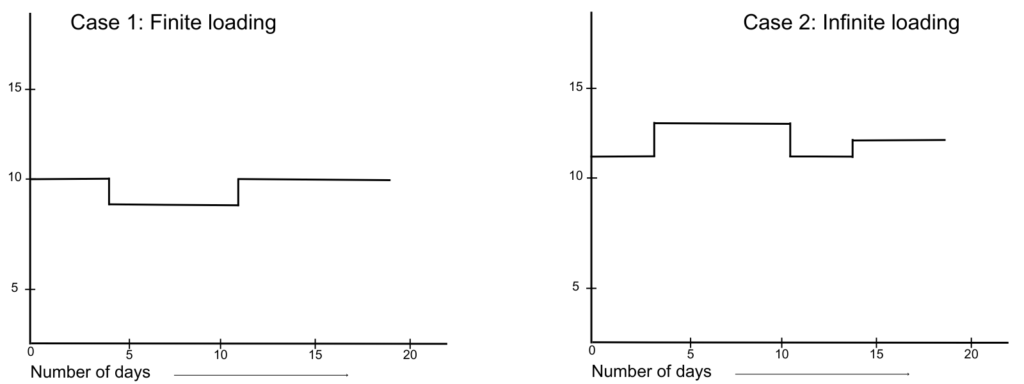

Every resource has a maximum production capacity for a normal working day. So when you keep in mind, this maximum capacity while loading the resources with tasks, it is known as finite loading. It involves assigning tasks in the resources such that the maximum capacity of the resource is not exceeded at any given point in time.

Let us draw a Gantt chart for a finite loading scenario.

Infinite loading means overlooking the max capacity of a resource while assigning tasks to it. This scenario usually happens when you have some orders which have been delayed and you want to catch up or when you have more orders than the capacity and still you want to deliver on time. So, you overload your resources. Workers have to perform overtime or hire more workers.